Pressure Seal Bonnet Wedge Gate Valve

| Casting | |

| Carbon Steel | WCB,WCC |

| Low Temperature Steel | LCB,LCC |

| Stainless Steel | CF8, CF8M, CF3, CF3M, CF8C, CF10, CN7M, CG8M, CG3M etc. |

| Alloy Steel | WC6, WC9, C5, C12, C12A |

| Duplex Steel | A890(995)/4A/5A/6A |

| Nickel-Based Alloy | Monel, Inconel625/825, Hastelloy A/B/C etc. |

| Forging | |

| Carbon Steel | A105 |

| Low Temperature Steel | LF2 |

| Stainless Steel | F304,F316,F321,F347 |

| Alloy Steel | F11,F22,F5,F9,F91 |

| Duplex Steel | F51,F53,F44 |

| Nickel-Based Alloy | Monel, Inconel625/825, Hastelloy A/B/C |

Manual, Gear box, Actuator operated, Pneumatic operated

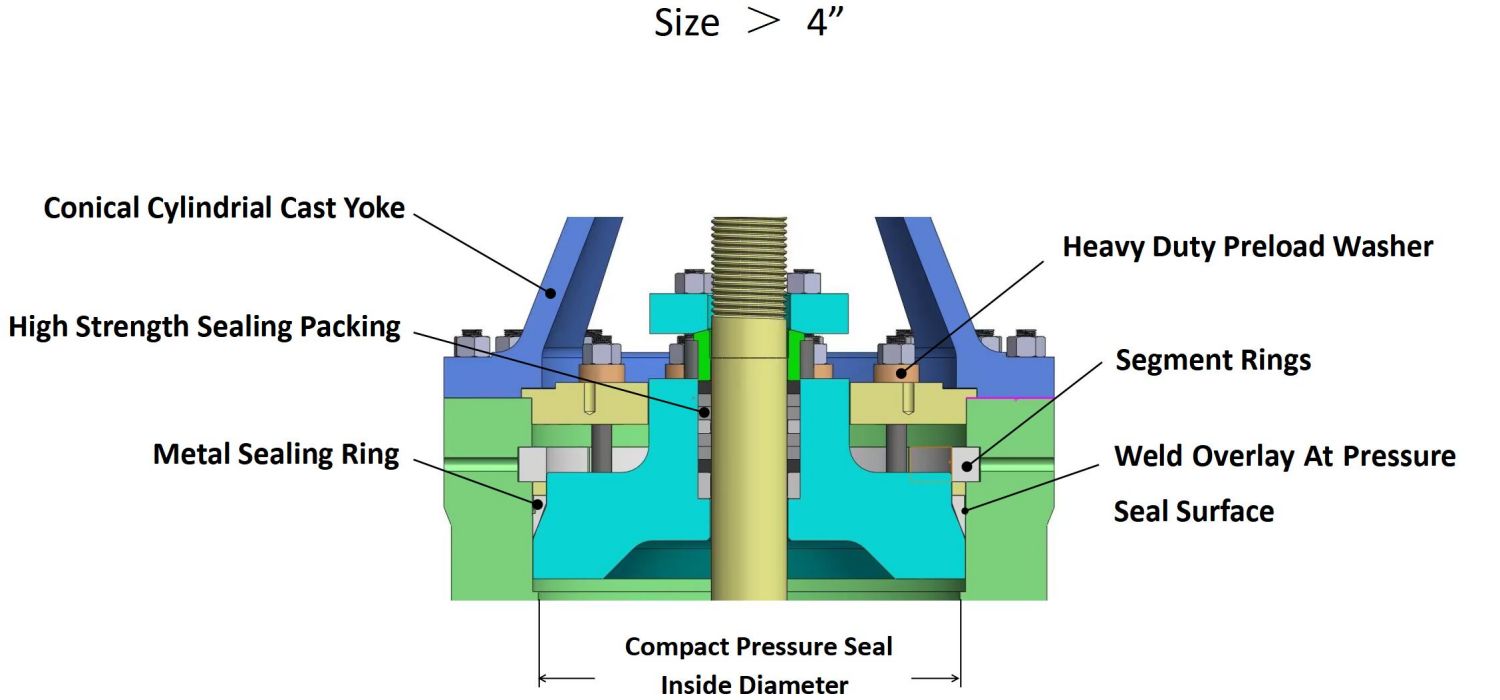

1. The design of Pressure Seal Gate Valve is specifically for high-pressure applications, therefore normally only available in pressure classes of 900# and above. These valves are unique because as their internal pressure increases, the body-bonnet joint seal improves.

2. The highlights of Nantong TH-Valve’s design is to use a smaller pressure space, which enables the greater pressure bearing and higher safety factor under the same wall thickness(API600 Heavy Duty).

3. Better seal capability with smaller angle of pressure seal and spring living load.

4. Comfortable operation experience with smaller operation force.

5. The full bore design is more energy-efficient, and the reasonable compact structure is suitable for the the concept of green development.

Trust in TH-Valve Nantong’s proven experience and expertise in large size, high-pressure Pressure Seal Gate Valve.

Contact us today to discuss your valve requirements and experience the greatness of working with a trusted valve factory.